滚珠丝杆直线模组的注意事项

来源:http://tianboo.net/ 日期:2023-12-28 发布人:

一 直线模组运用注意事项

创盈彩网址Precautions for using linear modules

模组工作中严禁直接触摸滑动座,要时间坚持待在工作范围。

创盈彩网址It is strictly prohibited to touch the sliding seat directly during module work, and it is necessary to stay within a safe working range for a long time.

滚珠丝杆模组产品笔直运用时,即在Z轴运用时,为防止物品掉落主张马达需装置刹车设备;齿轮皮带驱动不建议笔直运用。

创盈彩网址When using the ball screw module product straight, that is, when using on the Z-axis, it is recommended that the motor be equipped with a braking device to prevent objects from falling off; Gear belt drive is not recommended for straight use.

创盈彩网址当直线模组的有用行程过大(比如大于750mm )时可能会发生共振,行程越大时大速度应该相对的降低。

When the useful stroke of the linear module is too large (such as greater than 750mm), resonance may occur, and the larger the stroke, the relatively lower the speed.

二滚珠丝杆模组保养

Maintenance of the two ball screw module

创盈彩网址标准型滚珠丝杆模组保养

Standard ball screw module maintenance

创盈彩网址标准型直线模组保养添加光滑油脂时需先将上盖板拆下并接上黄油嘴注入恰当油脂

When maintaining the standard linear module and adding smooth grease, the upper cover plate needs to be removed first and the grease nozzle needs to be connected to inject appropriate grease

标准型直线滑台因受内部空间约束关系故保养注油经常有光滑不均匀的现象

Due to internal space constraints, the standard linear sliding table often experiences smooth and uneven lubrication during maintenance

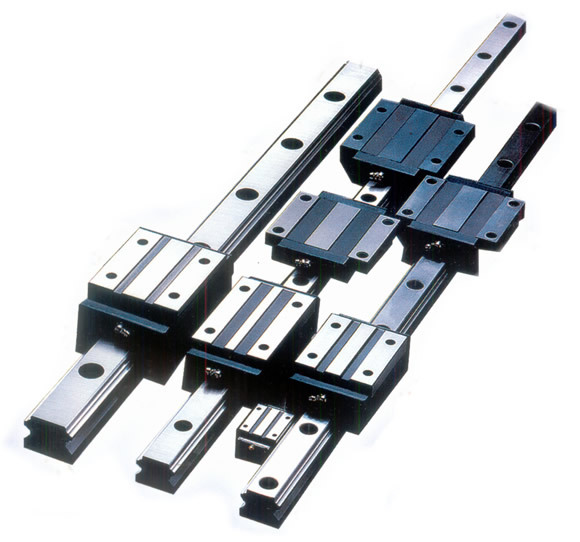

滚珠丝杆

ball screw

创盈彩网址全封闭型滚珠丝杆模组保养时直接由滑动座两侧油嘴注入油脂即可,不需拆装任何零组件,装置方便 ,运用简略;滚珠丝杆直线模组

When maintaining the fully enclosed ball screw module, grease can be directly injected into the oil nozzles on both sides of the sliding seat, without the need to disassemble any components, making the device convenient and easy to use; Ball screw linear module

创盈彩网址更多丝杆模组保养办法能够关注本站,持续为您提供直线模组运用指南。

For more maintenance methods for screw modules, please pay attention to this website and continue to provide you with a guide for using linear modules.

滚珠丝杆模组光滑办法

创盈彩网址Smooth method for ball screw module

创盈彩网址运用线性模块滑台时光滑是非常必要的,假如没有充分的光滑,工作时摩擦阻力会添加近而可能会成为缩短产品寿数的主要原因,而光滑方法大致分为手动光滑与主动强制光滑两种,可依照系统的运转速度’运用环境等 需求做恰当的选择

创盈彩网址It is necessary to use linear module sliding table for time sliding. If there is not sufficient smoothness, friction resistance will increase during operation and may become the main reason for shortening product life. Smooth methods can be roughly divided into manual smoothing and active forced smoothing, and appropriate choices can be made according to the system's operating speed, application environment, and other requirements

创盈彩网址光滑给油的频率依据运用条件与环境而有所不同, -般景象主张每运转100km弥补油脂一-次

The frequency of smooth oil supply varies depending on the application conditions and environment. Generally, it is recommended to compensate for oil and grease once every 100km of operation

- 上一篇:滚珠丝杆维修时要注意什么?

- 下一篇:滚珠丝杠加工设备有哪些?

导轨丝杠:滚珠丝杠常...<>

导轨丝杠:滚珠丝杠常...<> 导轨丝杠的作用<>

导轨丝杠的作用<>- 单张纸主滚筒支撑轴承...<>

丝杠导轨是什么<>

丝杠导轨是什么<> 丝杆导轨技术资料介绍<>

丝杆导轨技术资料介绍<>